Powering Racecars

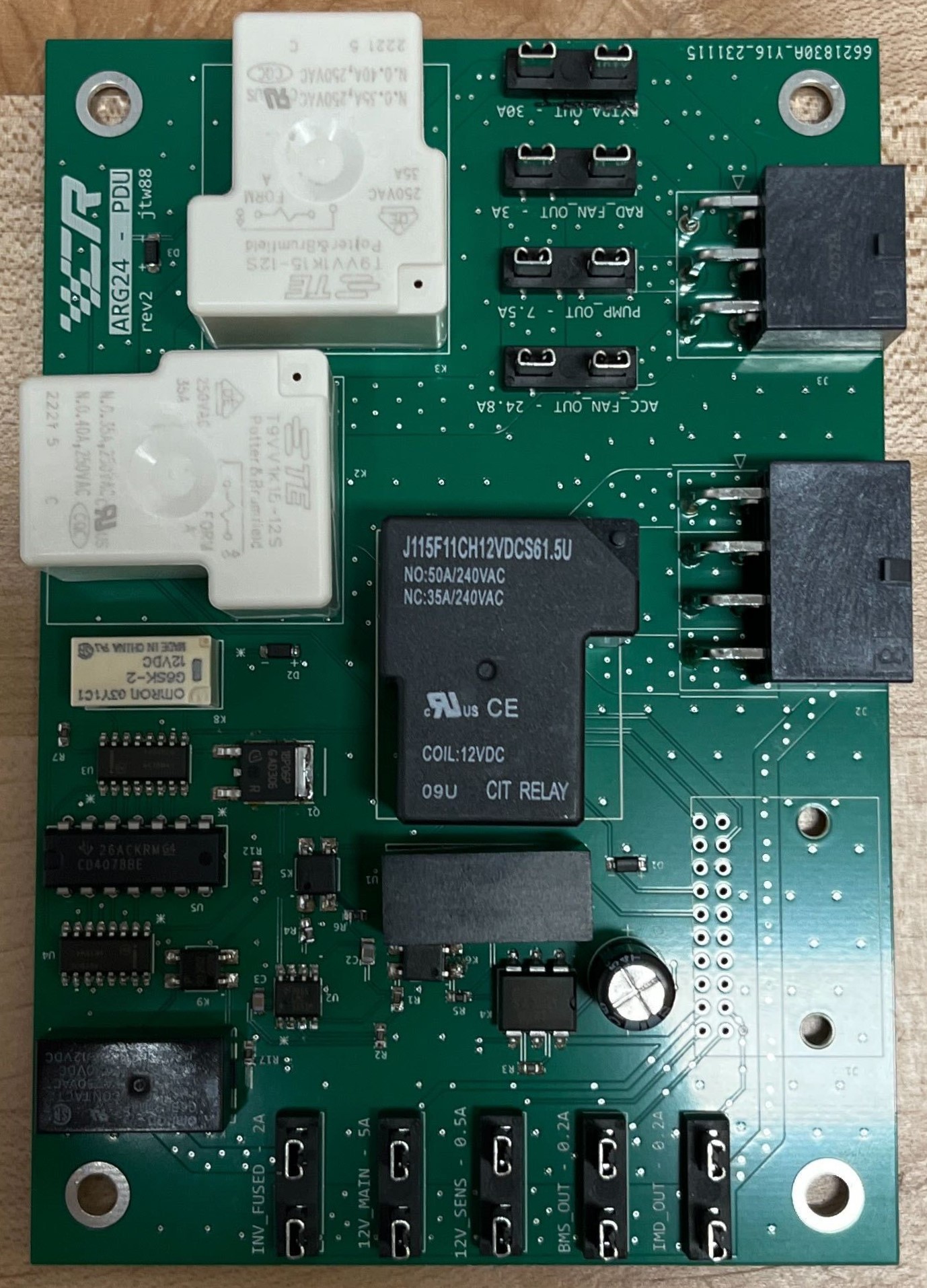

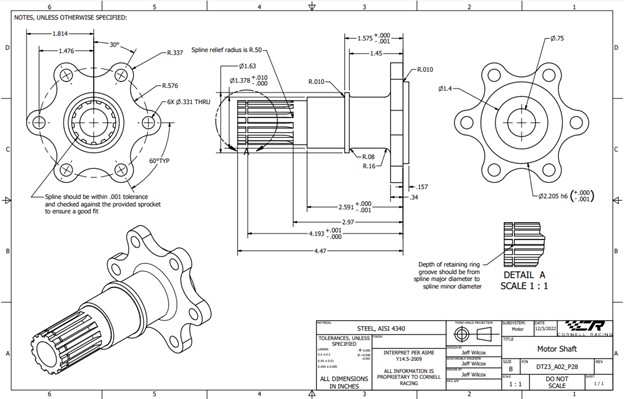

My first design role on the FSAE project team was focused on supporting components for the drivetrain system, such as mounts and spacers for sprockets, as well as a motor shaft. The following year, I decided to take on a more electrically focused role and worked on the Power Distribution Unit (PDU). This board was focused on routing regulated power to the correct systems across different states of the car. The main size and weight contributors are the high ampacity mechanical relays which route power to non-critical systems. Additionally, there is fusing to all power outputs as well as timing logic for an LED indicator mounted at the top of the car to indicate whether high voltages are present, a normal condition that warns observers to keep their distance to avoid danger. For more details, see my semester technical report below.